MEGATROM FDL

WE ARE BUSINESS BROKERS FOR THE WORLD

THE MEGATROM FDL HAS MANY INDUSTRIAL APPLICATIONS.

IN BRIEF A REVOLUTION

LBD Techologies (lbdtechnologies.com)

follow please

MEGATRON FOR MINING AND MUCH MORE

WE ARE ADVISOR FOR THIS TECHNOLOGY

A gas dynamic mill in which adiabatic resonance impact milling is implemented, with impact velocities close to the breaking threshold, can pulverize these materials.

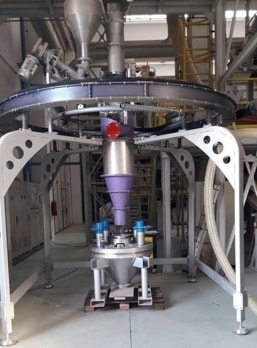

Such technology exists, it is called FDL (Lotus Flower) Megatron.

The equipment is capable of milling any material, from wheat grains to diamonds, thanks to the creation of zones in the vortex mill with a pressure gradient of up to hundreds of thousands of atm, thanks to the resonance generation of the multi-stage toroid.

________________________________________

FDL Megatron works on the basis of resonance frequencies, and reaches a frequency range from sonic to hypersonic (100 MHz and above). In such a wide spectrum of pulsed vibrations for ground material particles of any size, there is the frequency equal to the resonance frequency of a given particle or group of particles.

The FDL Megatron is capable of milling ultra-fine parts, measured in hundredths and thousandths of a micron (0.01-0.001 micron).

The FDL Megatron Resonance Vortex Mill is a gas dynamic mill that implements adiabatic resonant impact milling, with impact velocities close to the breaking point. Adiabatic expansion decreases the process temperature, preventing thermal degradation of the material being milled.

The milling chamber is a toroid and contains no rotating or rubbing parts, which prevents foreign material from being milled into the final product.

What the Fdl Megatron does we see in this video, made with a system in the "test" phase and still without the accessories that allow both to load it from above and to prevent the resulting dust from dispersing into the environment:

The Fdl Megatrons are designed to grind, dry and dehydrate many materials efficiently and easily, with performances that currently reach a production of 270 Mtonn/hour of treated material. The resulting pulverized material can then be selected and divided by resonance, and stored for subsequent recycling uses.

A suitable number of FDL Megatrons, placed in battery inside floating spheres equipped with Voith-schneider thrusters and gyroscopes, positioned with ocean tugs guided by GPS for long distances and by drones overflight for precision positioning, will be able to work on the floating and immersed material and transfer the resulting dust to the sorting units and from these to silos positioned on semi-submersible platforms.

The finely powdered, dehydrated, sterilized and divided into product categories material can be reused as raw material for the manufacture of products without the toxic characteristics that the material previously had.